Founded in 1964 by Larry C. Arant in the basement of his Northeast Charlotte home, Northeast Tool & Manufacturing represents two generations of family tradition in providing precision manufacturing services. For over five decades, we have been a preferred supplier of precision machined parts and complex assemblies for the aerospace, defense, energy, medical, and commercial industries.

1964

1964

Northeast Tool's Beginning- "PROVIDE"

Gifted with an entrepreneurial spirit, blessed with a keen awareness for business opportunities, and driven by the need to provide for his family, Larry C. Arant...

Northeast Tool's Beginning- "PROVIDE"

Gifted with an entrepreneurial spirit, blessed with a keen awareness for business opportunities, and driven by the need to provide for his family, Larry C. Arant founded Northeast Tool & Manufacturing Company in the 16’x 20’ basement of his Northeast Charlotte home. Larry began the journey of becoming a business owner outfitted with an old clausing lathe, a bench and belt grinder, a Rockwell mill, and a Delta Mill. He detected a need for a specialized machine shop that would take on unique manufacturing jobs such as the manufacturing of patents and textile components. Northeast Tool’s reputation grew as a machine shop that could design and manufacture specialized parts for larger corporations.

1971

1971

BUILDING FOR THE FUTURE

Larry recognized Northeast Tool's potential and knew that he could need to move his business to a location that would allow for growth and expansion. A brief relocation to Indian Trail, although more than...

BUILDING FOR THE FUTURE

Larry recognized Northeast Tool’s potential and knew that he would need to move his business to a location that would allow for growth and expansion. A brief relocation to Indian Trail, although more than three times larger, soon became overcrowded. Northeast Tool built upon another location to house its tooling and fabrication division to accompany an aggressive, custom designed tooling program.

1987

1987

EQUIPPING AND EXPANDING

Northeast Tool purchased its first Computer Numerical Control (CNC) Lathe to meet the market demands for specialized manufacturing and precision machined parts. Northeast Tool expanded its facilities by constructing a 20,000 sq...

EQUIPPING AND EXPANDING

Northeast Tool purchased its first Computer Numerical Control (CNC) Lathe to meet the market demands for specialized manufacturing and precision machined parts. Northeast Tool expanded its facilities by constructing a 20,000 square foot building that operates as the main manufacturing plant today. Additionally, Northeast Tool purchased three CNC mills to expand its manufacturing capabilities. Larry saw it was necessary to hire and train highly skilled craftsmen and with the support of his son began to establish a strong benchmark of talent. Many of those trained during this period still work and support the growth of Northeast Tool.

1996

1996

THE NEW FACTORY WORKER

Northeast Tool developed and established an elaborate training program for its team members that focused on core competency. This program was featured and recognized in Business Week magazine...

THE NEW FACTORY WORKER

Northeast Tool developed and established an elaborate training program for its team members that focused on core competency. Northeast Tool established a base line for each team member and formulated a prescription to match minimum competency. Northeast Tool incorporated a pay scale that allowed each staff member to take and complete training with a reward for competency. This program equipped Northeast Tool’s team with the knowledge to boost productivity and get ahead of the high-skills manufacturing trend. Northeast Tool was featured and recognized in Business Week magazine for its ambitious training program.

2005

2005

GLOBAL SUPPORT

Northeast Tool reached 90 team members across three shifts due to a continued effort of customer diversification. During this time, Northeast Tool was granted numerous contracts by Federal Defense...

GLOBAL SUPPORT

Northeast Tool reached 90 team members across three shifts due to a continued effort of customer diversification. During this time, Northeast Tool was granted numerous contracts by Federal Defense Contractors. These contracts allowed Northeast Tool to directly and positively impact Operation Iraqi Freedom by manufacturing detection devices, high caliber weaponry, and protection shields which saved United States Marine Warfighters every day. It was during this period Northeast Tool experienced its highest growth in revenues.

2014

2014

50 YEARS OF BUSINESS

The elements that contributed to Northeast Tool's early success still guide it today. Northeast Tool understands the importance of keeping up-to-date with precision machined parts in today's business environment. This importance was reiterated...

50 YEARS OF BUSINESS

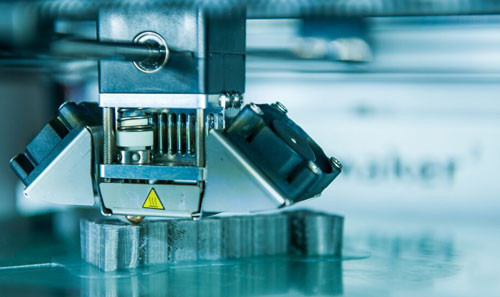

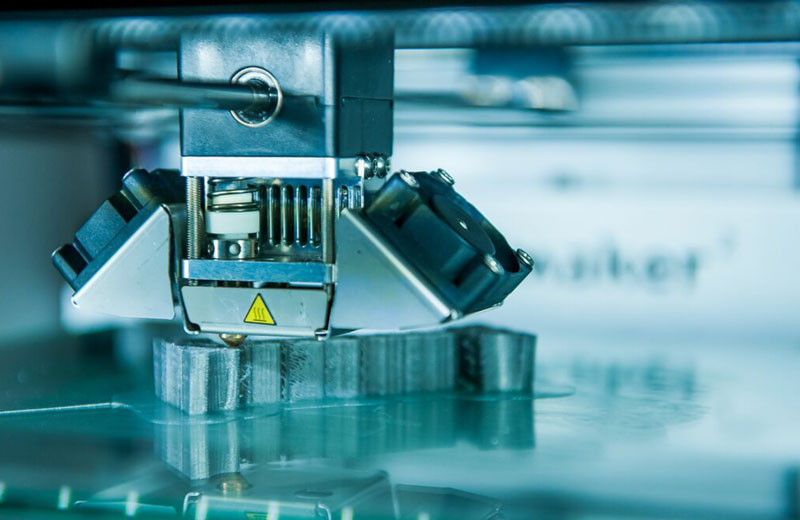

The elements that contributed to Northeast Tool’s early success still guide it today. Northeast Tool understands the importance of keeping up-to-date with precision machined parts in today’s business environment. This importance was reiterated during the tumultuous economic decline of 2008 – 2009. Northeast Tool used this time to improve its business plan with a revamped Sales Strategy to focus on growing markets. Northeast Tool implemented cost effective and efficient business hiring practices, and invested in automated machining processes.

Northeast Tool purchased and installed its first fully automated manufacturing cell including three horizontal turn-mill centers, a 6-axis Fanuc robot and fully integrated CMM. This cell reduces production time and allows for more specialized, higher tolerance processes in the future. The incorporation of monitoring and surveillance technology allows for greater flexibility to both Northeast Tool and its Customers.